From the last session where we finished installing the motor unit the next job was to bolt the main vertical post to the base box but...I'll put that on hold and build the upper wheel mount assembly which will make it easier to measure and cut the vertical post to ensure I have 70mm between the wheel centers, with the sliding wheel mounting block sitting on the bottom of its frame - more on this later.

The wheel block will sit inside a frame and I am cutting those pieces now, on the left is a stop block which ensures consistent accuracy of the cut lengths.

This is my Ozito 12" (305) sliding mitre saw  :-)

:-)

Most of the mitre saws in Bunnings are 10" or less, I had to deal directly with Ozito to get this beast over to the Scoresby store for pick-up without the need for any special order paperwork.

We'll need the router and...

the belt & disc sander.

TORX screws are my favourite these days, stocked up last time they came round at ALDI.

With the frame pieces cut here we are marking out to drill the pilot holes.

The frame needs to be precisely assembled to ensure that the hinged wheel block, which will have a 25mm steel tube running through it onto which the wheel mounted, moves in a true front-to-back arc for accurate blade tracking adjustments.

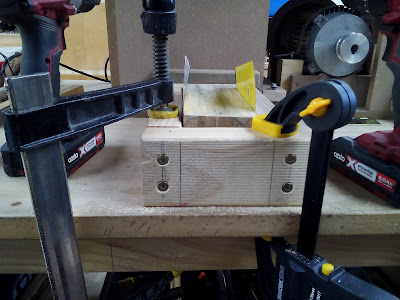

With the frame squeezed together and clamped to the workbench the cardboard shims ensure the wheel block has the desired clearance.

We can now drill and countersink the pilot holes.

With the bottom done we can turn the frame around to do the other end - the top.

Later on I will pull this apart for glue up, the numbers ensure it's assembled the same order. For blade tension adjustment this wheel block frame slides up and down inside the larger outer frame on slide tracks.

We now need to move to the router table to cut the slide tracks - see Part 2.

No comments:

Post a Comment